Outline

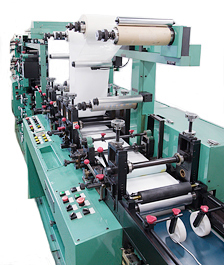

After 30 long years, you will find SKP-250A as one of the best selling presses. Advantages of both analog and digital technologies are incorporated over the years. No other press can perform for variety of works in one web pass as good as this press.

|

|

STANDARD EQUIPMENTS

Air shaft / Web guide system / Automatic ink washup system / Static eliminator / UV curing system (air-cooled 3.0KW)

OPTION EQUIPMENTS

Cookie die-cutting unit / Full die-cutting unit / Back printing unit / Flexo varnishing unit / Screen printing unit

Adhesive printing unit / Punching unit / Foil stamping unit / Laminating unit / Half die-cutting unit / Slitting unit / Sheet-cut unit |

| ■SPECIFICATIONS | |

| Max.web width (mm) | 250 |

| Max.print width (mm) | 235 |

| Print cylinders(T) | 50~150(158.75~476.25) |

| Die-cutting rollers(T) | 50~150(158.75~476.25) |

| Flatbed die-cutting length(T) | 50~100(158.75~317.5) |

| Sheet-cut length(T) | 50~100(158.75~317.5) |

| Printing speed (m/min) | 50 |

| Flatbed die-cutting speed (m/min) | 50 |

| Unwinder & rewinder (mmφ)/td> | 500 |

| Number of colors | 1~12 |

| Electric requirements | 3φ 200VAC 50A 17.3KVA(for 250mm press 7-color) |

Features

- Web guide system precisely guides any widths of web with latest supersonic sensor.

- Laminating unit overlaminates adhesive laminate film at a high speed.

- Die-cutting unit ensures high speed consistent die-cutting with rotary die roll.

- Sheet-cut unit ensures high speed consistent sheeting.

- Conveyor device delivers full cut or sheet-fed products.

- Flatbed die-cutting unit ensures powerful and consistent die-cutting.

- Slitting unit disposes of waste edges with vacuum.